SERVICES

Metal Framework Fabrication

A metal framework is a structure used to solve a complex issue, and at DFI we thrive off solving complex issues. Our metal framework fabrication services include Cutting, Shearing, Punching, Press Brake Forming, Rolling, Roll Bending, Machining, Welding, and Assembly. Frameworks can be fabricated in aluminum, stainless or steel depending on the application.

INDUSTRIAL CARTS

Here at DFI we know a thing or a thousand about intricate components, which is why we will help you transport your product in the same reliable and safe manner as we would our own parts. That’s why we fabricate custom carts, dollies, transportation racks, skids, and test stands for industrial use. Carts are usually made from stock steel, stainless steel, and/or aluminum however we work with all types of metals. We do the material cutting, welding, machining, and fabrication in house.

We support a wide variety of customer needs ranging from highly finished showcase quality carts to construction grade carts and bracketry. We fabricate material handling carts, tables, and frame weldments. We are capable of assembly of electronic components, such as motors and most supplied components. Our craftsmen work directly with you to fabricate a variety of industry fixtures to meet field-specific functionality and structural requirements. Dynamic Fabrication is AS9100 Rev D certified. We are an ITAR registered cart fabrication facility.

Here are examples of our skid, dolly, and cart fabrication:

- Custom material flow rack with heavy-duty swivel & rigid casters

- Aluminum handrail that is handicap accessible

- Brackets used on military vehicle for electrical radar components

- Maintenance platform custom-fabricated for easy access to machinery

- Hay bale mover crafted to easily transport large round bales of hay complete with trailer hitch

- Catwalk made with expanded metal created to allow a safe way to access assembly line

- Conveyor racking used for assembly line applications

- Custom fabricated electrical box used for custom-built machine

- Parts transfer cart used in a forktruck free environment

- Assembly cart used to assemble fork truck components

- Custom-built stock trailer

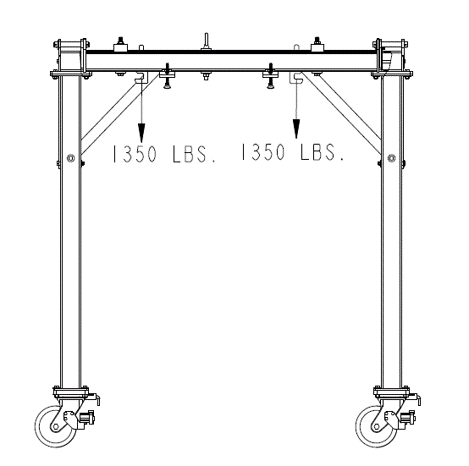

Aircraft Factory Assembly Frame.

Requirements: Weld, 100% Weld Visual Inspection, Create and Coordinate Load Test and

Develop Specialized Load Interfaces, Paint, Final Assembly with calibrated torque requirement

Material: Carbon Steel

Fabrication Software: Solidworks, TruTops Boost, MasterCam, PC-DMIS, DISCUS

Fabrication Processes: Laser Cutting, Lathe, Manual Mill, GTAW

Inspection Methods: Visual Inspection, Certified Load Testing, Laser Scanning